Patching small cracks with standard cement is difficult and time-consuming, especially if the damage is located in an area that is regularly exposed to water, like a concrete dock or the foundation of a home on the shore of a river, lake, or ocean.

Hydraulic cement is an effective solution that can be applied relatively easily. Learn more about what hydraulic cement is and what it’s used for.

What Is Hydraulic Cement?

Essentially, hydraulic cement is a liquid that, when exposed to water, rapidly dries and hardens to fix cracks, patch chips, or even build tough, water-resistant structures, like docks or dams.

This masonry repair and construction product is made up of four primary ingredients: alite, belite, celite, and brownmillerite. Both celite and brownmillerite keep the hydraulic cement in liquid form until it is ready for use. Alite and belite are the main reason for the strength and durability of this product after it has hardened.

Why Is Hydraulic Cement Needed?

Standard cement is tough, durable, and long lasting, so many people may question the need for hydraulic cement. However, this product more than meets expectations with a rapid setting time that takes just minutes for the hydraulic cement to solidify. This fast drying and hardening phase makes it ideal for quick projects around the home, while the water-resistance and rapid chemical reaction speed increases the use of this product for marine applications.

Hydraulic cement can be used above or below ground and it’s resistant to both chemicals and heat. This versatile product can be applied in wet or dry conditions, and is even capable of fully curing when exposed to high level of moisture. Due to the unique qualities of hydraulic cement, it has become an essential tool for a range of home repair, renovation, and remodeling jobs.

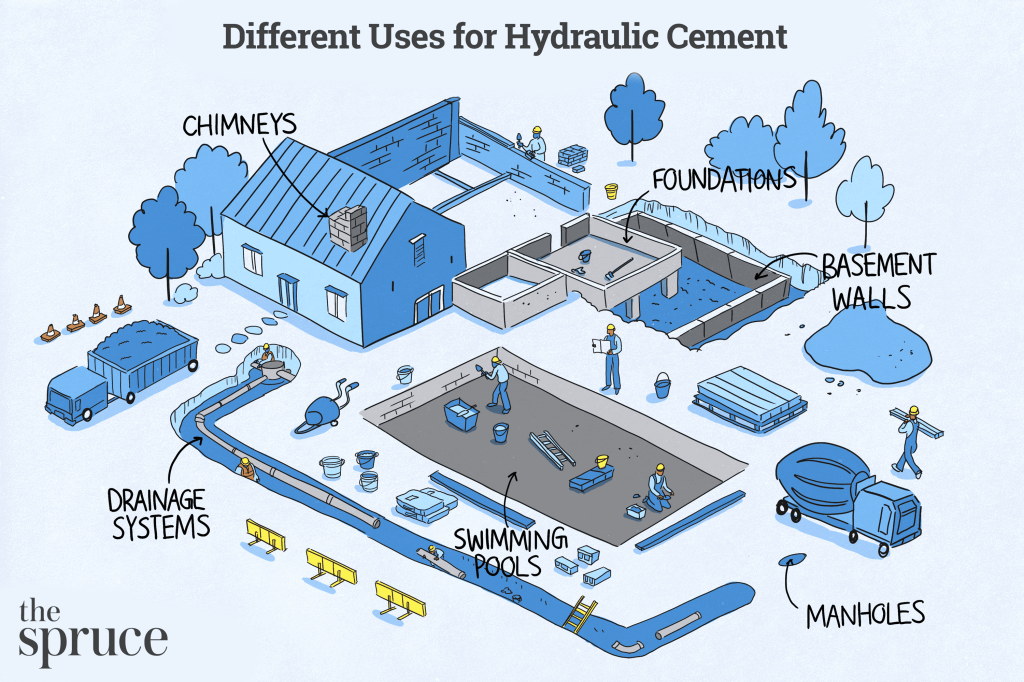

Hydraulic Cement Uses

Fixing Basement Wall Cracks

One of the more common uses of hydraulic cement is to fix minor cosmetic cracks in the basement wall. Small cracks can appear as a result of poor foundation drainage, water intrusion, or even the natural expansion and contraction of the concrete. Before patching the concrete, identify and fix the source of the problem.

Hydraulic cement dries and solidifies in minutes, so there isn’t a lot of time to work the mixture into the cracks. Don’t add water to the mix until you are ready to begin in order to maximize the amount of available working time.

Swimming Pool Repairs

The high level of water-resistance makes hydraulic cement an excellent choice for both wet and dry repairs, like fixing cracks or chips in the walls, floors, or deck of a concrete pool. Cracks in swimming pools can be caused by a variety of issues, such as temperature fluctuations, seasonal frost heaves, earthquakes, or gradual setting.

In order to repair the damage to the pool, you will need to drain and clean the affected surface to ensure the best adhesion possible. Cracks and chips that are left unaddressed can lead to bigger problems. The water may leak out of the pool and into the surrounding soil, or chipped concrete could put swimmers at risk of being cut, so make swimming pool repairs as soon as possible.

Filling Fountain and Cistern Cracks

Fountains with below-ground tanks, as well as cisterns, can be affected by hydraulic pressure when the water inside presses against the walls. Over time, this force can cause cracks to form, leading to leaks and water contamination. Even fountains that have aboveground tanks can develop cracks during seasonal temperature changes.

Hydraulic cement can be used to fill and repair small cracks in the fountain or cistern to stop leaks, though this may not prevent further damage from occurring. It’s important to determine the cause of the issue and take action to resolve the problem beyond minor patches. If the issue persists, the fountain or cistern may need to be repaired or replaced by a professional.

Patching Chimneys

When the heat from the fire rises up the chimney, the clay flue liners will expand. When the fire dies out and the air inside the chimney cools, the clay flue liners will contract with the changing temperature. This expansion and contraction can cause minor cracks to appear in the chimney.

Vertical cracks can be patched using hydraulic cement. These cracks are not a significant risk, but they should be repaired as soon as possible to prevent water from seeping through the chimney walls. However, it’s best to have a professional assess and fix horizontal chimney cracks, as these types of cracks can weaken the structure of the chimney, causing it to collapse.

Manhole Crack Repairs

Temperature changes are a common cause of manhole cracks, though poor drainage can also contribute to this problem. When the water seeps into the gap between the manhole and the soil, it gradually erodes the surrounding soil, causing the manhole to shift, settle, and inevitably crack. Similarly, if the soil is not compacted properly at the time of installation, the manhole may shift or sink, causing the structure to crack.

Hydraulic cement shouldn’t be used for serious cracks, but it can be an effective method for fixing small cracks or chips in the structure. The water-resistance and fast drying time helps ensure that the repair can be completed quickly without worrying too much about the existing moisture in the immediate environment.

Building Docks and Dams

Not all hydraulic cement can be used to build sturdy structures, like piers or retaining walls, but there are a options available with the appropriate level of strength and durability. Low heat of hydration hydraulic cement is a great option for large structures, like gravity dams. While this type of hydraulic cement has a long curing time, it gives off very little heat after being mixed with water, reducing the risk of cracks cause by thermal stress.

Similarly, high sulfate-resistant hydraulic cement has a long curing time, but this drawback is minor compared to the benefits. This type of hydraulic cement is used in piers, docks, and other structures that are exposed to seawater. The sulfate-resistance reduces the risk of the seawater damaging the structure.

Mending Drainage Systems

The purpose of a drainage system is to collect and disperse water in a way that reduces harm to the structure. Homes typically have a roof and gutter system that redirects the flow of water away from the foundation, but there are also concrete drainage systems that can be buried under ground to better control the flow of excess rain or meltwater.

When minor cracks occur, you can use hydraulic cement to fix the issue before it gets worse. The hydraulic cement can seal the drainage line, preventing water from leaking out into the soil. Though, extensive damage may require more serious repairs or could even lead to the replacement of the drainage line.

Sealing Masonry Structures

The rapid drying time and high level of water resistance makes hydraulic cement an ideal option for sealing minor leaks in rock or other masonry material. You can create a patch in minutes that will seal the structure and prevent moisture from seeping in, though this fix may not address the actual cause of the problem.

While hydraulic cement can be used for a temporary patch, this fix won’t last long if the pre-existing cause of the cracks in the masonry structure is not repaired. Hire a professional to assess the structure and make the necessary changes to resolve the problem. After this issue has been fixed, you can fill any cracks left behind with hydraulic cement.

Elevator Pit Patches

Elevators run up and down a shaft, stopping at each floor according to the button that is pressed. At the base of the shaft, there is a space between the shaft’s lowest landing door and the ground at the bottom of the shaft. This space is known as the elevator pit. Cracks can form in the elevator pit structure as a result of the floor or ground settling, though damage may also be caused from nearby equipment or vehicles.

If cracks are not patched, water can enter the pit, causing damage to the electrical equipment. Elevator repair professionals can use hydraulic cement to make quick fixes to the elevator pit. This will seal the shaft and prevent immediate damage, though it’s necessary to address the primary cause of the problem, otherwise the situation could get worse.

Foundation Repair

Similar to basement repairs, hydraulic cement can be used to make minor foundation repairs by filling cracks or patching small holes or chips. Though, it can be difficult to apply the hydraulic cement deep into a crack due to the rapid drying time, so it’s necessary for the DIYer to have everything ready to go before adding water.

This should ensure that they have the longest possible amount of time to apply the hydraulic cement before it solidifies. However, most foundation cracks and damage is due to external factors, like poor drainage, frost heaves, temperature fluctuations, or water intrusion. Look for ways to handle the primary cause of the damage to prevent further issues with the foundation.

Hydraulic Cement Health and Safety Precautions

Hydraulic cement must be handled very carefully and you must wear necessary PPE before applying. When working with hydraulic cement, it’s important to avoid breathing in any dust. Additionally, it’s recommended to wear safety glasses or goggles to prevent the cement dust from entering your eyes.

Ideally, you should be equipped with safety gloves, safety glasses, a mask or ventilator, closed-toe shoes, long pants, and a long-sleeve shirt.

-

What is the difference between hydraulic cement and regular cement?

Hydraulic cement is generally considered more durable than regular cement, and it can be used in wet or dry conditions, as well as above or below ground. However, regular cement will typically last longer than hydraulic cement and it’s more effective for patching thick or broad cracks, despite the long drying time.

-

Is hydraulic cement a permanent fix?

Hydraulic cement is best when used for minor patches or in moisture-heavy areas. Unfortunately, due to the rigidity of the structure after drying, hydraulic cement isn’t a permanent fix for concrete cracks. The expansion and contraction of the surrounding concrete can cause the cracks to grow. Additionally, a hydraulic cement patch doesn’t address the underlying cause of the problem, so before using this product, find and fix the source of the issue.

-

Does hydraulic cement stick to concrete?

Hydraulic cement will stick to concrete, though it’s important to thoroughly clean the edges and the surface of the concrete to prevent any dust or debris from obstructing the adhesive bond.

Read the full article here